How a well-specified BMS (and the right installation choices) unlocks safety, full cycle life, and predictable performance for LiFePO₄ systems

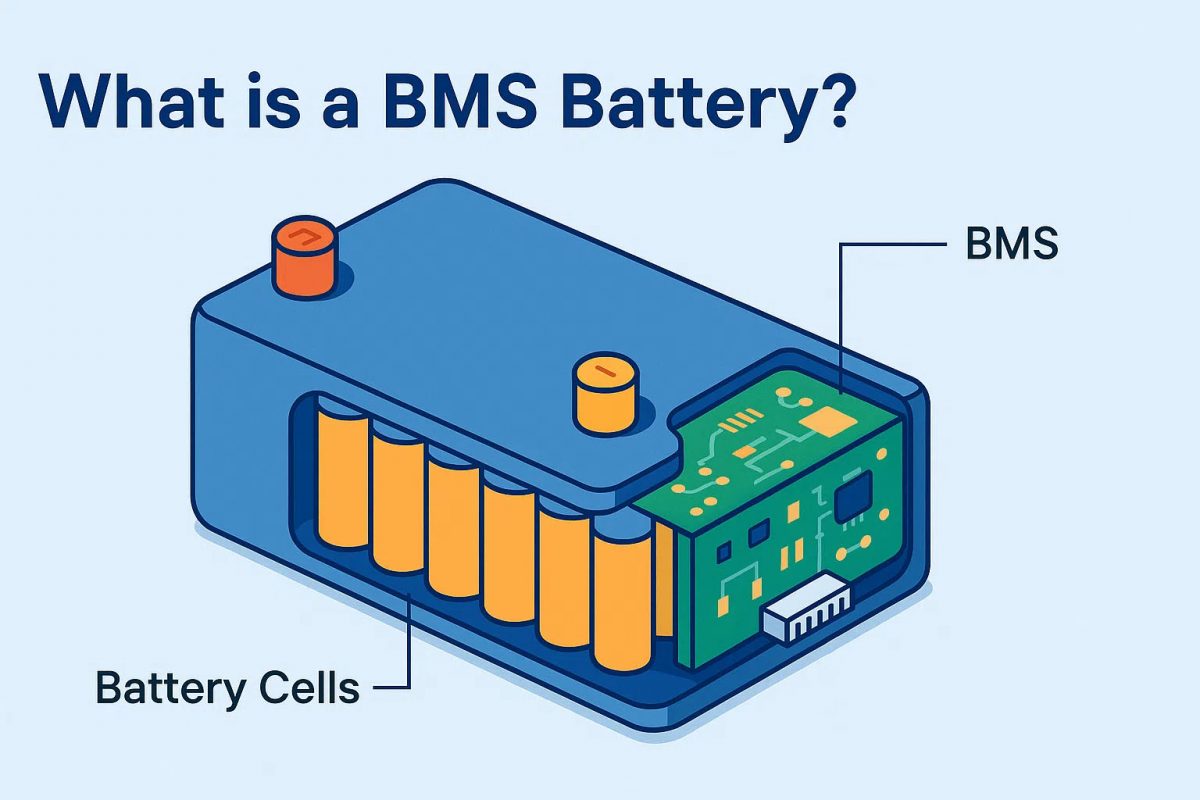

A Battery Management System (BMS) is the single most important electronic component in a LiFePO₄ (LFP) battery pack. It does more than "turn things off" when voltages go out of range — a properly chosen and configured BMS actively protects cells, balances them, and enables safe, predictable operation across charging, discharging and temperature extremes. In this article I walk through what a modern, fit-for-purpose BMS must do, how to choose the right one for your application, and the installation choices that preserve battery life and safety.

Why the BMS matters more for LiFePO₄ than it looks like

LiFePO₄ cells are chemically robust and offer excellent cycle life, but they still require precise control of voltage, current and temperature. Left unchecked, over-charge, deep discharge, excessive continuous current, cell imbalance, or thermal stress accelerate capacity loss and in rare cases create hazardous conditions. A BMS is the system’s defense: it monitors individual cell voltages and temperatures, performs cell balancing, enforces safe charge/discharge limits, and provides status/communication to chargers and inverters. Choosing one that only “cuts power” is asking for trouble; choose a feature set aligned with how the battery will actually be used.

Core capabilities to require from a BMS

When selecting a BMS for an LFP pack, insist on the following capabilities — they are non-negotiable for dependable, long service life:

• Accurate individual-cell monitoring and over/under-voltage protection. The BMS must continuously sample every series cell group and act before any cell crosses safe thresholds.

• Cell balancing (active or passive). Balancing corrects small state-of-charge differences that otherwise amplify over many cycles. For packs with many series cells or long service expectations, active or higher-quality passive balancing will measurably extend usable life.

• Thermal monitoring and protections. Temperature sensors (at least at module level) and temperature-based charge/discharge derating prevent accelerated aging and ensure safe operation in hot or cold climates. Consider BMSes that integrate thermal management strategies or at least expose thermal data to the host controller.

• Appropriate current rating and separate charge/discharge switching. The BMS continuous and peak current capability must exceed the maximum expected discharge/charge currents with margin; separate control of charge and discharge paths avoids being totally locked out when a single fault trips.

• Communication interfaces (CAN, UART, Bluetooth, etc.). Telemetry, alarms, and the ability to update or tune settings are essential for larger systems, grid/solar integration, or any professional installation.

Sizing a BMS to your pack and use case

BMS selection is fundamentally two-dimensional: voltage (number of cells in series) and current (continuous and peak). Match the BMS voltage range to the pack (e.g., 12.8 V nominal = 4s LFP; 51.2 V nominal = 16s, etc.) and choose a current rating comfortably above worst-case continuous draw (including inverter startup inrush and long-term charging current). For frequent high-current use or inverter duty cycles, select a BMS with higher continuous and surge capability rather than relying on fuse-only protection.

Practical tip: if the system may see short bursts of very high current, prioritize BMSes that separate charge and discharge switching (and that support configurable short-time surge ratings) so transient events don’t permanently lock out the pack.

Balancing: passive vs active — which matters for you?

Passive (resistive) balancing is common and cost effective for small to medium packs used under moderate conditions. Active balancing transfers charge between cells and is more efficient for large packs, long service life goals, or packs with frequent partial charges where state-of-charge divergence can grow over time. If your application targets maximum cycle life, large capacity banks, or grid/energy-storage installations, consider active balancing or high-quality passive balancing with tight voltage thresholds.

Thermal management: often overlooked, always important

Even though LFP tolerates higher temperatures than some chemistries, elevated pack temperatures accelerate calendar aging and reduce usable life. The best practice is to combine BMS thermal monitoring with either passive cooling strategies (airflow, placement away from heat sources) or active thermal control for installations exposed to wide ambient ranges. For electric-vehicle or high-power applications, a BMS that participates in a Battery Thermal Management System (BTMS) helps optimize performance while limiting degradation.

Integration: chargers, inverters and procedures

A modern BMS should interoperate cleanly with chargers and inverters. Prefer BMSes that provide clear signals for charge termination, pack-level state-of-charge (SoC) reporting, and fault diagnostics. During commissioning, verify BMS cut-in/out voltage settings and calibrate SoC if the system supports it. Document the configuration so service personnel know setpoints and derating behaviors.

Installation and commissioning checklist

To get the full expected lifetime from an LFP pack, follow this short checklist:

-

Verify BMS voltage-series support and current rating with margin.

-

Confirm cell balancing strategy and inspect balancing wiring/boards.

-

Place temperature sensors near the hottest expected region and validate thermal alarms.

-

Configure charge/discharge thresholds to match charger and inverter recommendations.

-

Run an initial health/soak test and record baseline voltages, resistances and SoC.

This practical commissioning saves hours of troubleshooting later and prevents many early-life failures.

Final considerations and common pitfalls

• Undersized BMS: Choosing a BMS that barely meets nominal current specs leads to nuisance trips or long-term overheating. Always add margin.

• No communication: A “dumb” BMS that only trips will hide problems until they become severe. Telemetry pays dividends.

• Skipping thermal sensors: Many sellers include them as optional — don’t skip them for high-power or outdoor installations.

• Assuming cell voltage = SoC: LFP’s flat voltage curve hides SoC — rely on coulomb counting and a properly configured BMS for accurate battery state estimation.

In short: choose a BMS that matches your pack’s voltage and current with margin; insist on per-cell monitoring and balancing; add thermal sensing; and pick communications that let you monitor and tune the system. Together, these choices transform LiFePO₄’s chemistry advantages into a durable, reliable energy system. For professional installations, brand RICHYE offer BMS modules and configurable systems that illustrate these best practices — but the selection principles above are what determine long life and safe operation, not branding alone.