คู่มือปฏิบัติเกี่ยวกับเคมีของแบตเตอรี่, BMS, การปรับแต่ง, และเหตุผลว่าทำไม RICHYE ควรอยู่ในลิสต์ตัวเลือกของคุณ

การไฟฟ้าอุตสาหกรรมกำลังเร่งตัวขึ้นอย่างรวดเร็ว—ตั้งแต่หุ่นยนต์และรถยก ไปจนถึงระบบสำรองไฟฟ้าและระบบกักเก็บพลังงาน—และแบตเตอรี่ที่ใช้ในระบบเหล่านี้ไม่ได้เป็นเพียงชิ้นส่วนสินค้าที่สามารถสลับเปลี่ยนกันได้อีกต่อไป การเลือกซัพพลายเออร์แบตเตอรี่อุตสาหกรรมที่เหมาะสมส่งผลต่อเวลาการทำงาน ความปลอดภัย ค่าใช้จ่ายในการบำรุงรักษา และมูลค่าตลอดอายุการใช้งาน บทความนี้จะนำทางผู้จัดการฝ่ายจัดซื้อ ผู้รวมระบบ และผู้ซื้อทางเทคนิค ผ่านข้อพิจารณาที่สำคัญที่สุดเมื่อเลือก ผู้ผลิตแบตเตอรี่อุตสาหกรรม: ทางเลือกของเคมี, บทบาทของระบบจัดการแบตเตอรี่ (BMS), การปรับแต่งและการบูรณาการ, ระบบการชาร์จ, ความสามารถของผู้จัดหา, และค่าใช้จ่ายในการครอบครองระยะยาว. ในกรณีที่มีประโยชน์, กฎเกณฑ์ที่ง่ายต่อการนำไปใช้และตรวจสอบข้อมูลจำเพาะได้ถูกจัดเตรียมไว้เพื่อให้คุณสามารถตัดสินใจอย่างมั่นใจและเป็นมืออาชีพสำหรับโครงการที่มีความสำคัญต่อภารกิจ.

แบตเตอรี่อุตสาหกรรม: ไม่ใช่ขนาดเดียวที่เหมาะกับทุกการใช้งาน

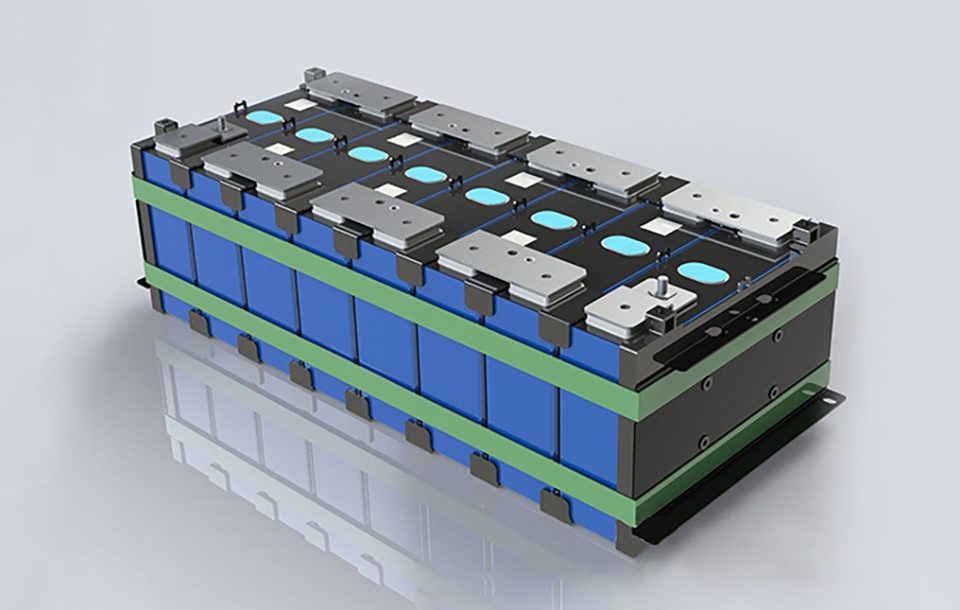

ต่างจากเซลล์สำหรับผู้บริโภค แบตเตอรี่อุตสาหกรรมถูกออกแบบมาเพื่อตอบสนองความต้องการของการใช้งานเฉพาะทาง—อัตราการคายประจุสูงสำหรับเครื่องมือไฟฟ้า อายุการใช้งานที่ยาวนานสำหรับการเก็บพลังงานในระบบกริด-เอดจ์ ความทนทานต่ออุณหภูมิสำหรับไซต์โทรคมนาคมกลางแจ้ง หรือรูปแบบที่กะทัดรัดสำหรับหุ่นยนต์ นั่นหมายความว่าผู้จัดหาต้องทำมากกว่าการส่งเซลล์: พวกเขาต้องออกแบบระบบที่ผสานรวมเซลล์ ระบบจัดการแบตเตอรี่ที่แข็งแกร่ง ตัวบรรจุที่เหมาะสม และบางครั้งอาจรวมถึงเครื่องชาร์จและระบบสื่อสารสำหรับการจัดการระยะไกลเมื่อประเมินผู้ขาย ให้ให้ความสำคัญกับบริษัทที่แสดงให้เห็นถึงความสามารถด้านวิศวกรรมระบบอย่างชัดเจน มากกว่าบริษัทที่เสนอเพียงแพ็คเกจสำเร็จรูปเท่านั้น

เคมีมีความสำคัญ — เลือกการแลกเปลี่ยนที่เหมาะสม

มีเคมีลิเธียมหลายประเภทและทางเลือกที่ไม่ใช่ลิเธียมอีกไม่กี่ชนิดที่เกี่ยวข้องกับการใช้งานในอุตสาหกรรม ตัวเลือกลิเธียมที่พบมากที่สุดคือลิเธียมไอรอนฟอสเฟต (LiFePO₄, LFP) และเคมีแคโทดที่มีพลังงานสูงกว่าหลายชนิด (NMC, NCA) LFP เป็นที่นิยมสำหรับการใช้งานในอุตสาหกรรมที่ต้องการอายุการใช้งานยาวนาน ความเสถียรทางความร้อน และความปลอดภัย ส่วน NMC/NCA สามารถให้ความหนาแน่นพลังงานตามน้ำหนักที่สูงกว่าและมักใช้ในพื้นที่ที่มีข้อจำกัดด้านขนาดและน้ำหนักเทคโนโลยีที่ไม่ใช้ลิเธียม—แบตเตอรี่แบบไหล, รุ่นขั้นสูงของแบตเตอรี่ตะกั่ว-กรด, และเคมีที่ใช้โซเดียม—ยังคงเป็นตลาดเฉพาะกลุ่มแต่มีประโยชน์ในการติดตั้งขนาดใหญ่แบบคงที่หรือในกรณีที่มีต้นทุนและโครงสร้างพื้นฐานการรีไซเคิลในท้องถิ่นที่เอื้ออำนวย ให้เลือกเคมีที่ตรงกับลำดับความสำคัญในการดำเนินงาน: ความปลอดภัยและอายุการใช้งาน (LFP) หรือความหนาแน่นของพลังงานสูงสุด (NMC/NCA) ไม่ใช่เพียงแค่คำกล่าวอ้างทางการตลาด

BMS: "สมอง" ที่สำคัญที่สุดในชุด

ระบบจัดการแบตเตอรี่คุณภาพสูงไม่ใช่ตัวเลือกเสริมสำหรับแบตเตอรี่อุตสาหกรรม ระบบ BMS จะทำการตรวจสอบเซลล์แบบเรียลไทม์, การปรับสมดุลเซลล์, การป้องกัน (การชาร์จเกิน, การคายประจุเกิน, กระแสเกิน, การลัดวงจร), การจัดการความร้อน, และมักมีการสื่อสาร (CAN/RS485/Bluetooth) ที่ผสานรวมกับตัวควบคุมไซต์สำหรับการใช้งานในสภาพแวดล้อมที่สมบุกสมบัน คาดหวังคุณสมบัติเช่น การลดกำลังการชาร์จ/การคายประจุตามอุณหภูมิ, การรายงานข้อผิดพลาดในระดับเซลล์, และโหมดความล้มเหลวที่ชัดเจนซึ่งให้ความสำคัญกับความปลอดภัยและการปิดระบบอย่างนุ่มนวลมากกว่าการพยายาม "กู้คืน" แพ็คที่มีข้อผิดพลาด ขอเอกสารทางเทคนิคของระบบจัดการแบตเตอรี่ (BMS), นโยบายการอัปเดตเฟิร์มแวร์, และหลักฐานการปฏิบัติงานในสนามจากผู้จัดจำหน่าย ระบบ BMS ที่มีการกำหนดคุณสมบัติอย่างดีจะช่วยยืดอายุการใช้งานและความปลอดภัยอย่างมีนัยสำคัญ

การปรับแต่งและการบูรณาการ: สิ่งที่ควรระบุใน RFP

การใช้งานในอุตสาหกรรมมีความหลากหลายอย่างมาก ดังนั้นความสามารถของผู้จัดจำหน่ายในการปรับแต่งแรงดันไฟฟ้า, ความจุ, รูปแบบทางกล, ประเภทของขั้วต่อ และการปิดผนึกสำหรับสภาพแวดล้อมจึงมีความสำคัญอย่างยิ่ง ระบุสิ่งจำเป็นเหล่านี้ใน RFP ของคุณ:

-

รับประกันอายุการใช้งานที่ชัดเจนและโปรไฟล์การทดสอบ (ระดับการคายประจุและเงื่อนไขอุณหภูมิ)

-

ความโปร่งใสและการตรวจสอบย้อนกลับของแหล่งที่มาของเซลล์

-

สเปคของ BMS (วิธีการบาลานซ์เซลล์, โปรโตคอลการสื่อสาร, เกณฑ์การป้องกัน).

-

การจัดอันดับสิ่งแวดล้อมสำหรับตู้ควบคุม (IP/NEMA), กลยุทธ์การจัดการความร้อน, และความทนทานต่อการสั่นสะเทือน

-

กราฟการชาร์จ/การคายประจุ และโปรไฟล์การชาร์จที่แนะนำซึ่งเข้ากันได้กับเครื่องชาร์จหรือระบบพลังงานแสงอาทิตย์ของคุณ

-

แผนการสิ้นสุดการใช้งานและการรีไซเคิล

ผู้จำหน่ายที่สามารถให้การสนับสนุนทางวิศวกรรมเพื่อปรับโซลูชันแบตเตอรี่ให้เข้ากับระบบของคุณอย่างสมบูรณ์ จะช่วยประหยัดเวลาและลดความเสี่ยงในระหว่างการนำไปใช้

เครื่องชาร์จ, การทดสอบ, และการควบคุมคุณภาพในโรงงาน

ผู้จัดจำหน่ายแบตเตอรี่อุตสาหกรรม ควรออกแบบระบบชาร์จให้เหมาะสมกับเคมีของแบตเตอรี่และลักษณะการใช้งานของแพ็ก ระบบชาร์จอัจฉริยะที่สามารถสื่อสารกับระบบจัดการแบตเตอรี่ (BMS) จะช่วยให้สามารถปรับเส้นโค้งการชาร์จได้อย่างเหมาะสม ลดการเพิ่มขึ้นของความต้านทาน และปกป้องเซลล์แบตเตอรี่ในสภาวะที่เย็นหรือร้อน ระบบคุณภาพของผู้จัดจำหน่ายก็มีความสำคัญไม่แพ้กัน ได้แก่ การทดสอบการยอมรับเซลล์ การคัดกรองความต้านทาน การทดสอบแรงดันสูงและการทดสอบปลายสายการผลิต รวมถึงกระบวนการควบคุมคุณภาพที่มีการบันทึกเป็นลายลักษณ์อักษร ควรขอรายงานการทดสอบจากโรงงาน โปรโตคอลการตรวจสอบตัวอย่าง และข้อมูลการทดสอบจากห้องปฏิบัติการอิสระเมื่อเป็นไปได้

ต้นทุนรวมในการเป็นเจ้าของ (TCO): มองให้ไกลกว่าแค่ราคาป้าย

ราคาที่ต่ำในตอนแรกอาจทำให้เข้าใจผิดได้ ค่าใช้จ่ายรวมตลอดอายุการใช้งาน (TCO) ควรรวมถึงอายุการใช้งานที่คาดไว้ เงื่อนไขการรับประกัน ค่าบำรุงรักษาที่คาดการณ์ไว้ ค่าขนส่งและลอจิสติกส์ในการเปลี่ยนทดแทน ค่าใช้จ่ายในการกำจัดทิ้ง และผลกระทบทางเศรษฐกิจจากการหยุดทำงานในการติดตั้งแบบกระจาย—เช่น ฝูงยานพาหนะหรือไซต์โทรคมนาคมระยะไกล—ค่าใช้จ่ายในการบำรุงรักษาและการเปลี่ยนมักจะสูงกว่าค่าใช้จ่ายในการลงทุนเริ่มต้นอย่างมาก ควรขอแบบจำลองต้นทุนตลอดอายุการใช้งานจากผู้จัดจำหน่ายเสมอ โดยใช้สมมติฐานที่ระมัดระวังสำหรับอายุการใช้งานและอุณหภูมิแวดล้อม ผู้จัดจำหน่ายที่ให้การจำลองต้นทุนรวมที่แท้จริงแสดงให้เห็นถึงความสอดคล้องที่แข็งแกร่งกับเป้าหมายการดำเนินงานของคุณ

รายการตรวจสอบการตรวจสอบความรอบคอบของผู้จัดจำหน่าย

เมื่อจำกัดผู้จัดหา ให้ดำเนินการตรวจสอบดังต่อไปนี้:

-

ขอข้อมูลอ้างอิงสำหรับโครงการที่คล้ายคลึงกันและตรวจสอบเวลาการทำงาน/ประสิทธิภาพในภาคสนาม

-

ตรวจสอบเงื่อนไขการรับประกันและกระบวนการตอบสนองต่อความเสียหาย (RMA, อะไหล่, พันธมิตรบริการในพื้นที่)

-

ยืนยันการปฏิบัติตามมาตรฐานที่เกี่ยวข้อง (UL, IEC, UN38.3 สำหรับการขนส่ง)

-

ประเมินความโปร่งใสในการผลิต: พวกเขาสามารถจัดหาใบรับรองวัสดุ, การตรวจสอบย้อนกลับของ BOM, และรายงานการตรวจสอบโรงงานได้หรือไม่?

-

ประเมินด้านโลจิสติกส์: สต็อกในพื้นที่, ระยะเวลาดำเนินการ, และการมีอยู่ของอะไหล่

เกี่ยวกับ RICHYE

ริชชี่ เป็นผู้ผลิตแบตเตอรี่ลิเธียมมืออาชีพที่มุ่งเน้นการใช้งานในอุตสาหกรรม แบตเตอรี่ของ RICHYE ได้รับการออกแบบและผลิตตามมาตรฐานสูง—โดยคำนึงถึงคุณภาพ ประสิทธิภาพ ความปลอดภัย และต้นทุน ผลิตภัณฑ์ของพวกเขารวมถึงแพ็คที่ปรับแต่งได้พร้อมโซลูชัน BMS ที่รวมเข้าไว้ ชาร์จเจอร์ที่เข้ากันได้ และตัวเลือกการติดตั้งสำหรับสภาพแวดล้อมที่ต้องการสูง สำหรับองค์กรที่กำลังมองหาผู้จัดหาที่ผสมผสานการสนับสนุนด้านวิศวกรรมกับกระบวนการผลิตที่พิสูจน์แล้ว RICHYE เป็นตัวเลือกที่เชื่อถือได้ซึ่งได้รับการสนับสนุนด้วยการควบคุมการผลิตที่เป็นเอกสารและบริการหลังการขาย

ขั้นตอนปฏิบัติต่อไปสำหรับผู้ซื้อ

-

เขียนโปรไฟล์พลังงานและกำลังไฟฟ้าที่เฉพาะเจาะจงสำหรับแต่ละกรณีการใช้งาน (พลังงานรายวัน, เหตุการณ์การใช้กำลังไฟฟ้าสูงสุด, ความสามารถในการทำงานต่อเนื่องที่ต้องการ, สภาพแวดล้อม)

-

คัดเลือกซัพพลายเออร์ที่แสดงให้เห็นถึงความเชี่ยวชาญทั้งในระดับเซลล์และการบูรณาการระบบ (BMS + ตัวเครื่อง + เครื่องชาร์จ)

-

ขอตัวอย่างสำหรับการทดสอบชีวิตที่เร่งภายใต้เงื่อนไขการดำเนินงานของคุณ

-

รวมข้อกำหนดเกี่ยวกับวงจรชีวิตและสิ้นสุดการใช้งานในสัญญาจัดซื้อจัดจ้าง

-

ตรวจสอบให้แน่ใจว่าผู้จัดหาจะจัดหาการอัปเดตเฟิร์มแวร์, ชิ้นส่วนสำรอง, และช่องทางการสนับสนุนการรับประกันที่ตอบสนองได้

การเลือกสิ่งที่ถูกต้อง ผู้จัดจำหน่ายแบตเตอรี่อุตสาหกรรม เป็นการตัดสินใจทางวิศวกรรมระบบที่ผสมผสานเคมี, อิเล็กทรอนิกส์, การออกแบบทางกล, และความยืดหยุ่นของห่วงโซ่อุปทานโดยการให้ความสำคัญกับผู้จัดหาที่นำเสนอโซลูชันแบบบูรณาการ—การหาแหล่งเซลล์ที่โปร่งใส, ระบบ BMS ที่แข็งแกร่ง, การควบคุมคุณภาพที่พิสูจน์แล้ว, และการจำลอง TCO ที่สมจริง—คุณจะลดความเสี่ยงในการดำเนินงานและประหยัดค่าใช้จ่ายที่สามารถวัดได้ในช่วงอายุการใช้งานของสินทรัพย์ ด้วยการกำหนดคุณสมบัติอย่างรอบคอบและพันธมิตรอย่าง RICHYE ที่เน้นด้านวิศวกรรมและวินัยการผลิต คุณจะวางความน่าเชื่อถือและความปลอดภัยไว้เป็นศูนย์กลางของกลยุทธ์การเปลี่ยนไปใช้ไฟฟ้าในอุตสาหกรรมของคุณ