A practical, professional guide to chemistry, management, safety, and ROI — with RICHYE battery insights for today’s material-handling fleets

Selecting a 24-volt battery is no longer a simple price-vs-size decision. Modern material-handling operations demand energy systems that deliver predictable runtime, fast charging, low maintenance, long life, and clear total cost-of-ownership advantages. This guide walks fleet managers, engineers, and procurement professionals through the technical and commercial criteria that actually matter — with practical tips for evaluating suppliers like RICHYE and for specifying batteries that perform in real workplaces.

1. Start with the use case: duty cycle, power and runtime

Before you compare chemistries, define how the battery will be used. Key parameters are average load, typical shift length, number of cycles per day, and whether opportunity charging (short top-ups during breaks) is available. A battery that looks good on spec sheet can underperform if its rated cycle life or usable capacity doesn’t match the real duty cycle. Establish a realistic energy budget (Wh per hour under expected loads) and require vendors to demonstrate performance under those conditions.

2. Chemistry matters: why LFP (LiFePO₄) is the leading practical choice

For 24-volt industrial packs, lithium iron phosphate (LFP) chemistry has become the de-facto standard for a reason: it combines long cycle life, robust thermal stability and good abuse tolerance compared with older lithium formulations and with flooded lead-acid cells. LFP packs deliver substantially higher usable cycle counts and do not require watering or the same level of preventive maintenance as lead-acid systems — a major operational advantage for busy warehouses.

When evaluating suppliers such as RICHYE, ask for cell datasheets that specify cycle life at relevant depths-of-discharge (DoD). A realistic expectation for quality LFP cells is multiple thousands of cycles at moderate DoD; low-quality cells will show much shorter life in real operation.

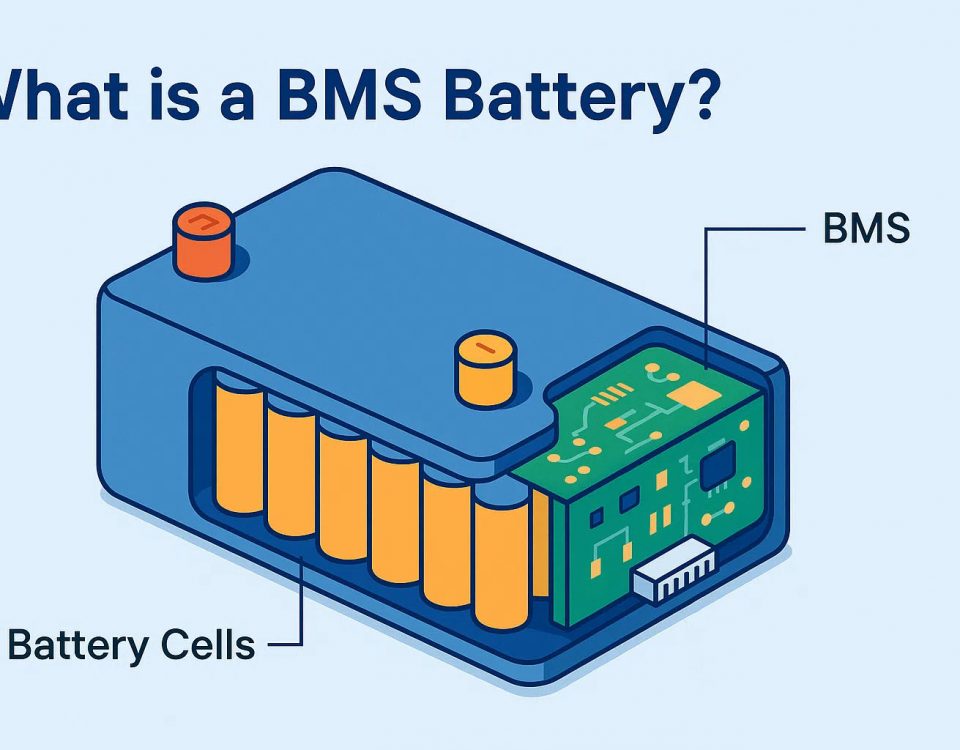

3. Battery Management System (BMS): the brain that protects and extends life

A high-quality BMS is not optional — it is the difference between a battery that lives to spec and one that fails prematurely. The BMS should manage cell balancing, over/under-voltage protection, over-current protection, temperature monitoring, and state-of-charge (SoC) estimation. Advanced systems also provide state-of-health (SoH) reporting and firmware that supports adaptive charging curves and predictive maintenance alerts. If a supplier’s BMS lacks clear diagnostics or telematics outputs, that’s a red flag.

Require suppliers to show BMS test logs or live telematics samples from comparable installations. Pay attention to how the BMS handles fault isolation and whether it can be updated in the field.

4. Charge strategy and thermal management: fast charging safely

Faster charging increases uptime but also raises thermal and electrochemical stress on cells. Effective thermal management — either passive (heat-sinking, enclosure design) or active (air/liquid cooling in larger packs) — is essential to maintain cell temperatures within safe windows during high-rate charge cycles. A battery that advertises “fast charge” should come with independent test data showing capacity retention and temperature behavior after repeated fast-charge cycles.

When vetting RICHYE or other vendors, request cycle test data showing degradation after X fast charges (e.g., 80% state after 1,000 fast cycles), and confirm what thermal protections are built into the pack and BMS.

5. Efficiency and operating cost: energy, charging losses and ROI

Lithium-ion (LFP) systems are typically more energy efficient than lead-acid — meaning less energy lost in the charge/discharge process and lower electricity costs for the same delivered work. They also accept charge faster and can eliminate the need for costly battery changeovers or spare batteries for long shifts. While upfront cost is higher, the combination of longer life, reduced maintenance, and higher operational uptime usually yields a favorable total cost of ownership for many fleets. Ask vendors for a TCO model that includes purchase, installation, electricity, maintenance, and end-of-life disposal/recycling assumptions.

6. Mechanical and electrical integration: fit, vibration and connectors

A 24-V pack must physically and electrically integrate with the host vehicle. Check mechanical tolerances, vibration resistance, connector types, and ingress protection (IP) ratings. Confirm that the pack can be mounted securely and that its center-of-gravity change will not affect vehicle stability. Standardized, rugged connectors and clear polarity/locking features reduce installation errors and downtime.

7. Safety certifications, standards and warranty

Insist on documented compliance with relevant standards (UN38.3 transport testing, IEC cell/pack standards, and any local regulatory requirements). The vendor should provide test certificates and a clear, written warranty that defines what is covered, the warranty length, and how capacity loss is measured. For industrial applications, a two-year minimum warranty with pro-rated coverage for capacity fade is a reasonable baseline; premium suppliers may offer longer terms tied to demonstrated cycle life.

8. Monitoring, telematics and serviceability

Modern battery systems should offer telematics: SoC/SoH reporting, charging history, temperature trends, and alarm logs. These data enable preventative maintenance and allow procurement to compare actual field performance against promised metrics. Evaluate whether RICHYE’s telemetry integrates with your fleet management system and whether remote firmware updates are possible.

9. End-of-life planning and sustainability

Ask about a clear take-back or recycling pathway. Responsible vendors provide options for cell recycling or refurbishment, and transparent policies for handling packs at end of life. This is increasingly important for both regulatory compliance and corporate sustainability reporting.

10. Practical checklist to evaluate suppliers (quick)

-

Chemistry & cell datasheets (LFP preferred for industrial 24V).

-

BMS features and sample logs (balancing, SoH, telematics).

-

Thermal management & fast-charge testing data.

-

TCO analysis including energy efficiency and maintenance.

-

Mechanical fit, connectors, IP rating, vibration tests.

-

Certifications (UN38.3, IEC) and warranty terms.

-

Service network, spare parts, and recycling policy.

Closing: specify for reality, not for the brochure

Technical specifications are only as useful as their real-world validation. When you request bids, send a clear duty-cycle profile and require vendors to demonstrate performance under those exact conditions. Ask for sample packs or pilot installations whenever possible, and compare field data from comparable customers. Suppliers who can show independent cycle testing, robust BMS telemetry, and transparent end-of-life programs (as RICHYE does for its industrial line) earn a real advantage — because they reduce operational risk and produce measurable savings over the life of the asset.

Choosing a 24-volt battery is a systems decision: chemistry, electronics, thermal design, and lifecycle economics must all align with your operation’s realities. With careful specification and by holding vendors to measurable field performance, you’ll turn a high-cost, high-risk purchase into a predictable asset that increases uptime and lowers total cost of ownership.