Proven operational rules and new technologies that keep people, inventory, and productivity protected

Forklifts are the backbone of warehouse operations — moving pallets, loading trailers, and keeping orders flowing — but they’re also a leading source of workplace injuries and costly damage when safety is an afterthought. A practical, modern forklift-safety program combines clear procedures, operator competence, well-maintained equipment, and intelligent use of technology. This article gives warehouse leaders and frontline supervisors a professional, actionable roadmap to reduce risk and improve uptime.

Start with a strong safety culture

Safety begins at the top. A visible commitment from management — consistent enforcement of rules, timely investigations of near misses, and recognition of safe behaviors — sets the tone. Safety culture isn’t about zero tolerance slogans; it’s about systems that make the safe choice the easy choice: clear processes, accessible training, and reliable equipment.

Key actions:

-

Hold regular toolbox talks that are short, specific, and actionable.

-

Empower staff to report hazards and near-misses anonymously if they prefer.

-

Track safety performance with simple KPIs (near-miss rate, training completion, inspections completed) and use the data to target improvements.

Operator training and licensing

Competent, certified operators are the single most important control. Training should be hands-on, role-specific, and regularly refreshed — classroom time alone is not enough.

What good training covers:

-

Equipment controls, attachments, and limitations (rated capacity, load center, mast tilt).

-

Pre-operation inspections and what to do if defects are found.

-

Load handling techniques: secure stacking, stable lift heights, and correct travel positions (forks low and tilted back when moving).

-

Traffic rules inside the facility: speed limits, intersection behavior, and horn use.

-

Pedestrian awareness and communication.

Refresher training should follow incidents, observed poor performance, or when new equipment is introduced. Consider partnering with a reputable training provider such as RICHYE for standardized courses and competency evaluations.

Pre-shift inspections and preventive maintenance

A daily checklist prevents predictable failures. Operators should perform a quick pre-shift inspection and log the outcome. Maintenance teams must act promptly on reported faults.

Inspection items to require:

-

Tires, forks, and mast condition.

-

Hydraulic lines, visible leaks, and fluid levels.

-

Steering and braking responsiveness.

-

Lights, horns, and safety devices (seatbelt, interlocks).

-

Battery condition and secure mounting.

A preventive maintenance schedule keyed to hours of operation, not just calendar days, avoids mid-shift breakdowns that tempt unsafe shortcuts.

Workplace layout, traffic control, and pedestrian zones

Warehouse design plays a major role in safety. Poorly organized traffic lanes, blind corners, and cluttered aisles create hazards that good driving alone can’t overcome.

Design principles:

-

Separate pedestrian walkways and forklift lanes wherever possible, using physical barriers, painted aisles, or raised walkways.

-

Install mirrors and clear signage at intersections; use marked stop lines and right-of-way rules.

-

Maintain clear sightlines: keep shelving and inventory within racking limits and avoid ad hoc stacks in travel ways.

-

Implement speed limits tailored to environment — slower where pedestrians mix with vehicles.

Weekend or overnight cleanups and daily housekeeping reduce slip/trip hazards and keep emergency access routes clear.

Managing loads and rated capacity

Every lift must respect the truck’s rated capacity at the actual load center and lift height. Overloading, uneven loads, and high lifts increase tip-over risk.

Best practices:

-

Confirm load weight and placement before lifting. Use scales when weight is uncertain.

-

Use attachments only when they are rated for the truck and task. Attachments alter the truck’s load chart and must be accounted for.

-

Travel with forks low (but not dragging) and tilt the mast back to stabilize the load.

-

When stacking, place heavier pallets at the bottom and orient loads to prevent shifting.

Pedestrian safety and communication

Most forklift-related injuries involve pedestrians. A combination of engineering, administrative controls, and behavioral rules reduces these events.

Recommendations:

-

Require high-visibility apparel in mixed-traffic areas.

-

Establish clear pedestrian-only areas for order picking and staging.

-

Use audible warnings, spotters, and hand signals during tight maneuvers.

-

Train pedestrians in hazard awareness: don’t assume the operator can see you; stay out of blind spots.

Leverage technology — wisely

Modern safety technologies don’t replace fundamentals but amplify them. Thoughtful deployment reduces human error and provides data for continuous improvement.

Useful technologies:

-

Telematics and fleet management: Track utilization, idling, speed events, and operator behavior to target coaching and maintenance.

-

Proximity detection and collision avoidance: Systems that warn operators or automatically slow a truck when it nears a person or another vehicle reduce impact risk.

-

Cameras and 360° vision systems: Improve visibility in congested or high-shelf environments.

-

Automatic speed limiters and geofencing: Enforce slower speeds in designated pedestrian zones or near loading docks.

-

Automated Guided Vehicles (AGVs) and AMRs: When integrated safely, autonomous vehicles can remove humans from particularly hazardous, repetitive tasks — but they require rigorous segregation and control strategies while coexisting with manned traffic.

Vendors like RICHYE offer integrated telematics and sensor packages; choose systems that provide useful, actionable alerts rather than noise.

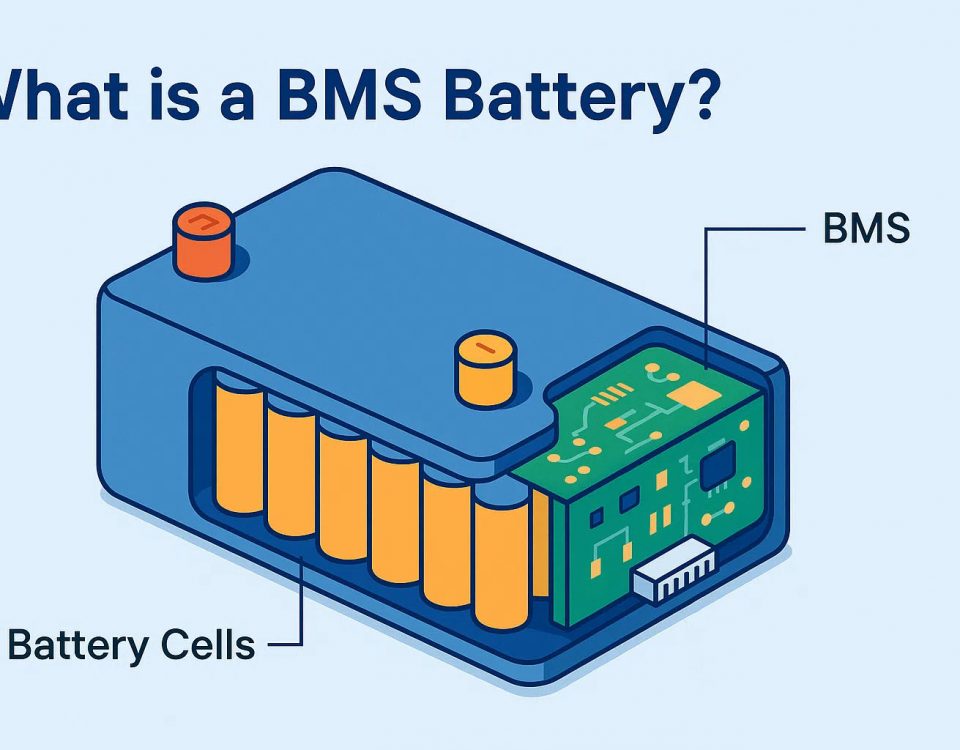

Battery and charging safety (for electric fleets)

Electric forklifts reduce emissions but introduce battery-handling hazards. Whether using lead-acid or lithium-ion, safe battery practices are essential.

Key points:

-

Train staff on battery change-out procedures and safe charging-room behavior.

-

Provide adequate ventilation for charging areas; keep chargers and battery cells clean and well-maintained.

-

Implement lockout/tagout procedures for battery maintenance.

-

For lithium-ion systems, follow manufacturer guidance on charging profiles, thermal monitoring, and fire-suppression considerations — these packs require different controls than traditional flooded lead-acid batteries.

Incident response and continuous improvement

Even the best systems fail sometimes; how you respond matters. A standardized incident response and robust near-miss reporting system prevent recurrence.

Action items:

-

Have a clear emergency plan and make it visible and practiced (fire, tip-over, spill, injury).

-

Conduct root-cause analyses for incidents to find systemic fixes rather than blaming individuals.

-

Share lessons learned in briefings so the whole team benefits from every investigation.

Closing the loop: measurement and leadership

Safety programs that don’t measure outcomes fade. Track both lagging indicators (injuries, lost time) and leading indicators (training completion, inspection rates, near-miss reports) and review them monthly with operations and safety staff. Celebrate improvements and address persistent gaps with resources — training, layout change, or technology — based on data.

Forklift safety is an operational imperative, not a compliance checkbox. By combining competent operators, disciplined inspections, purposeful workplace design, and targeted technology like telematics and proximity sensing, warehouses can run faster and safer. Implement these measures deliberately, measure their effect, and your facility will move closer to that goal everyone shares: zero crashes, full productivity.