Discover how slow and fast charging impact battery health, performance, and longevity—and choose the ideal RICHYE charging solution for your needs

In today’s electrified world—where everything from power tools to electric vehicles runs on lithium batteries—understanding charging speed isn’t just a matter of convenience. It directly affects your battery’s cycle life, operating temperature, and ultimate performance. While fast chargers promise rapid turnaround, slow chargers often deliver gentler charging curves that can extend battery longevity. This article dives deep into both approaches, examines recent technological advances, and offers actionable guidance to help you choose the right charging strategy for your ริชชี่ lithium battery.

The Fundamentals of Lithium Charging

Lithium-based chemistries, including lithium iron phosphate (LiFePO₄) and lithium nickel manganese cobalt (NMC), follow a multi-stage charging profile:

-

Constant Current (CC) Stage: Charger delivers maximum current up to a pre-set voltage—typically 3.6–3.7 V per cell for LiFePO₄ or 4.1–4.2 V per cell for NMC.

-

Constant Voltage (CV) Stage: Voltage remains fixed while current tapers down as the cells approach full charge.

-

Termination/Float Stage (if supported): Charger stops or holds a trickle to offset self-discharge, though most lithium batteries do not require extended float charging.

A slow charger applies a lower constant current—often 0.1C to 0.3C (10–30% of battery capacity per hour)—while a fast charger may push 0.5C to 1C (or more in specialized designs), filling the pack much faster.

Pros and Cons of Slow Charging

Advantages

-

Enhanced Cycle Life: Lower currents generate less heat, reducing stress on electrode materials and electrolyte, which can increase cycle life by up to 20%.

-

Better Cell Balancing: Extended CV stage duration allows the battery management system (BMS) to equalize cell voltages more thoroughly.

-

Reduced Thermal Management Needs: Slower charging keeps pack temperatures within an optimal 50–80 °F range, preventing accelerated aging.

Drawbacks

-

Longer Downtime: Charging a 100 Ah pack at 0.1C takes approximately 10–12 hours to reach full state-of-charge (SoC).

-

Limited Opportunity Charging: Not ideal for mid-day top-ups when quick turnaround is essential.

Best Applications: Maintenance charging overnight, seasonal top-offs, and scenarios where maximum battery lifespan is the priority.

Pros and Cons of Fast Charging

Advantages

-

Rapid Turnaround: A 0.5C charge rate can replenish 80% of capacity in just 1–2 hours, ideal for high-utilization applications like EV fleets or heavy equipment.

-

Opportunity Charging Friendly: Quick top-ups during breaks avoid the need for spare batteries or extended downtime.

Drawbacks

-

Increased Heat Generation: Higher currents produce more internal resistance heating, which, if not managed, can accelerate cell degradation.

-

Potential for Imbalanced Cells: Faster tapering in the CV stage may not allow enough time for complete cell balancing, leading to capacity loss over time.

-

Demanding Thermal Management: Requires robust cooling systems or thermal cutoffs to prevent overheating.

Best Applications: Commercial or industrial use where uptime is critical, such as delivery vehicles, rental fleets, or production-line machinery.

Advances in Fast-Charge Technology

Recent innovations have narrowed the gap between speed and longevity:

-

Improved Electrode Materials: High-rate LiFePO₄ formulations and silicon-blended anodes tolerate faster charge currents with less degradation.

-

Adaptive Charging Algorithms: Smart chargers dynamically adjust current and voltage based on real-time cell temperature and SoC, optimizing the CC/CV transition.

-

Liquid-Cooling and Phase-Change Materials: Integrated cooling plates and thermal buffers absorb heat spikes during rapid charging, holding pack temperature within safe limits.

-

Bidirectional Inverters: In EVs and energy storage systems, inverters can redirect regenerative braking and solar input for faster “on-the-go” recharge.

These breakthroughs enable RICHYE’s high-performance charger lineup to deliver 0.8C–1C charge rates without sacrificing cell health—provided adequate thermal controls are in place.

Matching Charger Speed to Your Use Case

-

Residential Energy Storage & Overnight Tools

-

Recommendation: Slow charging (0.1C–0.2C) to preserve cycle life for home backup batteries or power-tool packs.

-

Rationale: Regular overnight charging aligns with user habits and keeps thermal stress minimal.

-

-

Commercial Electric Vehicles & Fleet Equipment

-

Recommendation: Fast charging (0.5C–1C) paired with active cooling.

-

Rationale: Minimizes downtime between shifts; modern lithium chemistries and BMS systems mitigate accelerated wear.

-

-

Portable Medical Devices & Emergency Equipment

-

Recommendation: Moderate charging (0.2C–0.5C) using adaptive chargers.

-

Rationale: Balances quick readiness with strict safety requirements and long-term reliability.

-

-

Outdoor & Field Applications

-

Recommendation: Dual-mode chargers that auto-switch between fast and slow based on pack temperature and SoC thresholds.

-

Rationale: Ensures rapid top-ups when needed, then tapers to gentle finishing charge to protect cells.

-

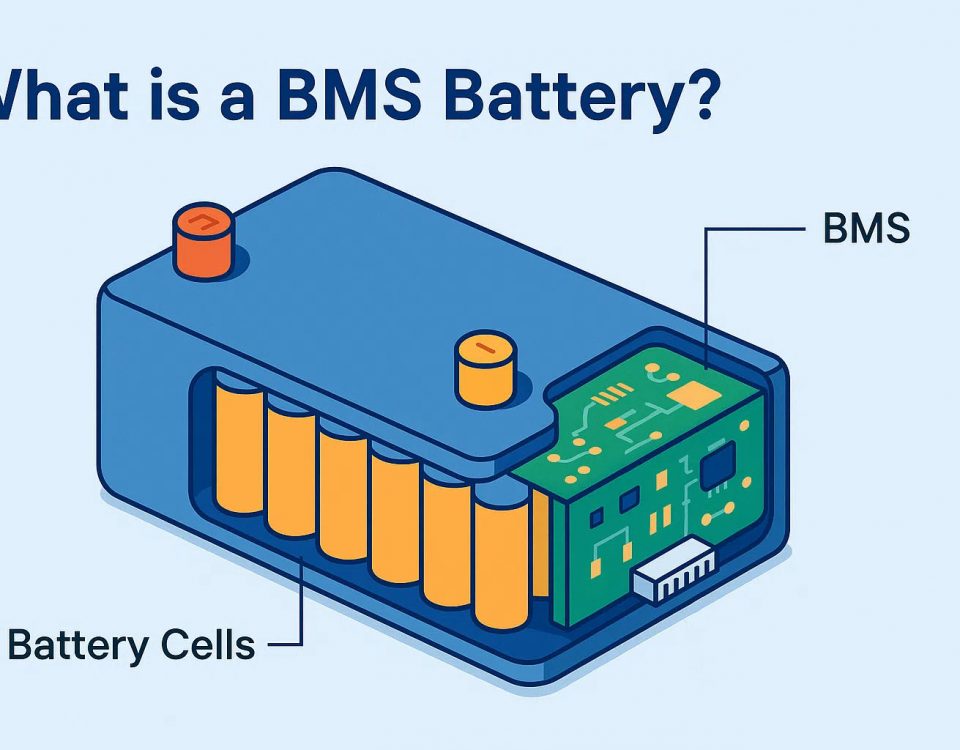

The Critical Role of Battery Management Systems

A sophisticated BMS is non-negotiable for any fast-charging setup. Key features include:

-

Real-Time Temperature Sensing: Cell and pack thermistors feed data to the charger, triggering current reduction if thresholds are exceeded.

-

Dynamic SoC Estimation: Coulomb-counting and voltage-based algorithms refine charge cut-off points to avoid overcharge while maximizing usable capacity.

-

Cell-Level Balancing: Active balancing circuits redistribute charge between cells during CV mode, preventing weak cells from limiting pack performance.

-

โปรโตคอลการสื่อสาร: CANbus or SMBus interfaces allow chargers, inverters, and external monitoring systems to coordinate charging profiles seamlessly.

RICHYE’s lithium battery packs integrate these BMS functions, ensuring that whether you choose slow or fast charging, your cells remain within their ideal operating envelope.

Practical Tips for Safe, Efficient Charging

-

Maintain Ambient Temperatures: Charge in a climate-controlled environment (ideally 50–80 °F). For extremes, use battery-heaters or cooling fans.

-

Use Charger-Chemistry Matching: Always pair chargers rated for your specific lithium chemistry (LiFePO₄ vs. NMC) and nominal voltage.

-

Avoid Frequent Full Charges at High Rates: If possible, stop at 80–90% SoC during fast charges and finish with a slow “top-off” overnight.

-

Monitor C-Rate Limits: Never exceed the manufacturer’s recommended maximum charge current—typically 1C for most lithium packs without active cooling.

-

Regular Firmware Updates: Keep your charger and BMS firmware current to benefit from improved charge algorithms and safety features.

Cost vs. Benefit: Total Cost of Ownership

While fast chargers carry a higher unit cost—often due to more robust electronics and cooling systems—their ability to increase asset utilization and reduce spare battery inventory can yield significant ROI. Conversely, slow chargers are less expensive upfront and simpler to maintain, making them ideal for applications where charging windows are ample and cycle counts are moderate.

When calculating total cost of ownership:

-

Evaluate Downtime Costs: How much does each hour of equipment idle time cost your operation?

-

Factor Battery Replacement Frequency: Estimate cycle life reductions under different charge regimes.

-

Consider Energy Efficiency: Higher-rate chargers may incur greater heat losses; review their charge acceptance efficiency ratings.

-

Account for Infrastructure: Cooling systems, ventilation, and electrical upgrades can add to fast-charger deployment costs.

บทสรุป

Choosing between slow and fast charging for your แบตเตอรี่ลิเธียม isn’t a binary decision; it’s a strategic choice that balances speed, cycle life, safety, and budget. By understanding the underlying electrochemical principles, leveraging modern fast-charge technologies, and deploying a robust RICHYE BMS, you can tailor your charging approach to match your operational goals. Whether you prioritize maximum runtime and longevity or rapid turnaround and heavy utilization, the right charger will empower your equipment—and your bottom line—to perform at its best, day in and day out.